Domestic polycrystalline alumina fiber and its types have developed slowly in the past 20 years. Although polycrystalline mullite fiber manufacturers have doubled, their manufacturing processes and equipment are basically a replica of transplantation. Although mullite fiber acupuncture There are some improvements in the blanket, but there is no improvement in quality. The polycrystalline alumina fiber is basically stagnant. Only a few large scientific research units in the country are researching and developing functional alumina continuous fibers, but the industrial intermediate room is actually high. Aluminum fiber inspection conditions are not yet available, which requires joint development and production with domestic large-scale ceramic fiber production companies.

Polycrystalline Mullite Fiber Cotton

The development trend of alumina fiber at home and abroad, a good preparation process of alumina fiber is one of the important factors to increase its development speed. Therefore, exploring new methods of preparing alumina fibers is the research focus of many researchers. Although it has developed greatly in recent years, it still has great development potential compared with general refractory materials.

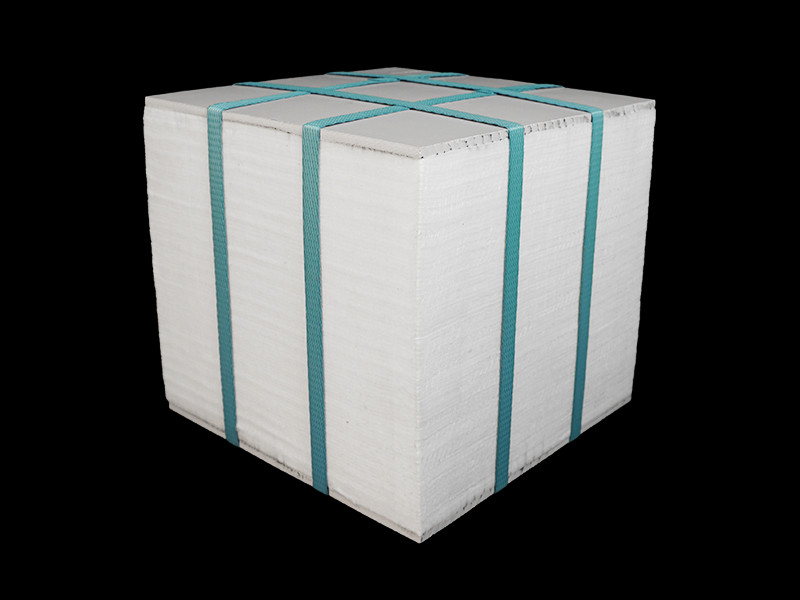

Polycrystalline alumina fiber module

The future development direction is to develop a series of polycrystalline refractory fiber related products with higher service temperature and better performance, which can meet various special requirements. For example, polycrystalline refractory fiber is used as raw material to produce fiber castables, plastics and coatings to replace traditional refractory materials such as refractory bricks and unshaped refractory materials, and to give full play to the excellent performance of polycrystalline refractory fiber materials in terms of energy saving and environmental protection. Expand The scope of use of polycrystalline refractory fibers serves my country's energy strategy and promotes sustainable economic development. At the same time, improve the preparation process, strengthen the performance optimization of alumina fiber reinforced metal matrix composites, and open up a broader market for alumina fibers. The preparation technology and product quality of alumina fiber in my country are much behind that of foreign countries, especially the process control of the production process is basically manual operation. During the calcination process of the green body, there is no uniform system and specification for the heating temperature, the uniformity of the furnace temperature, and the speed of grain formation. The market application is limited, so it is of great significance to strengthen the research on fiber preparation technology and application field for the development of my country's alumina fiber industry.