The core manufacturing technology of alumina fiber needle-punched blanket has been strictly blocked by developed countries due to its outstanding product advantages, and my country has long relied on imports for this product. Alumina fiber (polycrystalline mullite fiber) is the best among refractory fiber materials. It not only has excellent high-temperature creep resistance and thermal shock resistance, but also can show a variety of effects after being combined with other materials through a special process. Alumina fiber can be called the most "hot" ultra-high temperature and variety refractory material at present.

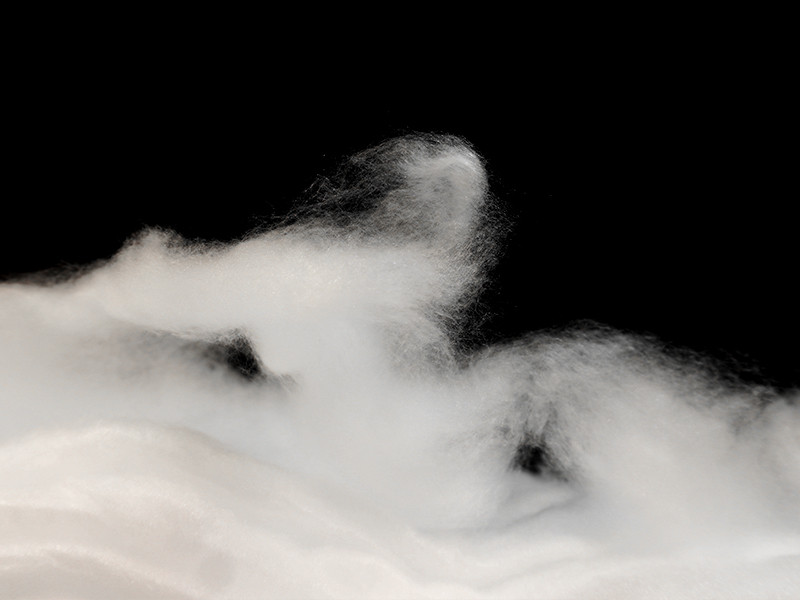

Combining alumina fiber with different refractory materials, inorganic binders and high-temperature fillers can be "transformed" into a wide variety of lightweight high-temperature-resistant fireproof materials, which have excellent energy-saving effects in high-temperature furnaces above 1250. "Among the alumina fiber products, the most representative one is the alumina fiber needle-punched blanket."

A very large application market for alumina fiber needle-punched blankets is the three-way catalytic converter sealing gasket in the exhaust gas treatment equipment of the high-end automobile industry. At present, the sealing gasket in the automotive industry is monopolized by companies such as Japan's Mitsubishi, Japan's IBIDEN, and the United States 3M. In addition, alumina continuous fiber can be processed into alumina yarn and alumina fiber cloth, which is an excellent material for high-temperature and fire-resistant fields such as aerospace, national defense and military industry. As a high-end refractory fiber product that can be produced in a few countries in the world, alumina fiber needle-punched blanket has outstanding product advantages, and its core manufacturing technology has been strictly blocked by developed countries. For alumina fiber needle-punched blanket products, my country has relied on imports for a long time, and their uses have been strictly restricted.

Inorganic fibers such as alumina fiber, zirconia fiber, silicon carbide fiber, and carbon fiber are all military materials that are being developed by the country and belong to the country's key demand materials. Developed countries in Europe and the United States use it as a strategic reserve material, and impose a technical blockade on my country. Some products are banned from sale, and non-banned products are sold at high prices and in limited quantities. achieve mass production.

The successful development of alumina fiber needle-punched blankets solved the key equipment problems restricting the industrialization of alumina fibers, realized the industrialization and localization of alumina fibers, broke the technical blockade of European and American countries, and provided key materials for the military industry to promote The major development of high-end industries such as aerospace and military industry has laid a solid foundation; upgrading the manufacturing technology of high-tech inorganic fibers in my country has driven major breakthroughs in high-tech fiber industries such as zirconia and silicon carbide; reducing the procurement cost of alumina products for domestic enterprises has contributed to the national Save a lot of foreign exchange funds.